NIPPON KUHLERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NIPPON KUHLERS

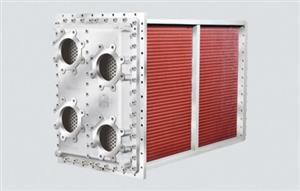

Inter Coolers

An intercooler is any mechanical device used to cool a fluid, including liquids or gases, between stages of a multi-stage heating process, typically a heat exchanger that removes waste heat in a gas compressor. They are used in many applications, including air compressors, air conditioners, refrigerators, and gas turbines Intercoolers increase the efficiency of the induction system by reducing induction air heat created by the supercharger or turbocharger and promoting more thorough combustion. This removes the heat of compression (i.e., the temperature rise) that occurs in any gas when its pressure is raised or its unit mass per unit volume (density) is increased.

After Coolers

An aftercooler was the cooler whose outlet fed the engine. Some systems had a cockpit control for opening or closing a damper to the intercooler/aftercooler, providing another way to control temperature.

Aftercoolers are heat exchangers for cooling the discharge from a air compressor. They use either air or water and are an effective means of removing moisture from compressed air.

Aftercoolers control the amount of water vapor in a compressed air system by condensing the water vapor into liquid form. In a distribution or process manufacturing system, liquid water can cause significant damage to the equipment that uses compressed air. An aftercooler is necessary to ensure the proper functionality of pneumatic or air handling devices that are a part of process manufacturing systems. Aftercoolers can use either air-cooled or water-cooled mechanisms.

Steam Driers Air Heater

We offer our clients, a wide range of Industrial Air Heaters that is used to heat air with radiant heat, forced convection or resistive heat elements. These used steam, hot water of electricity and thermic fluid oil for excellent functioning. Our range is designed as per industry quality standards and norms, and has gained appreciation from the clients due to its performance, durability, corrosion resistance and dimensional accuracy.

These are used in various industries for heating continuous flow of air to required temperature by using steam as heating media.

Steam is passed inside the finned tubes bunks and air outside the tubes. These types of Air-Pre-Heaters find application in papers mills, sugar mills , power plants etc.

Finned Tubes

Finned Tubes are always used in air-cooled exchangers to compensate for the low air side heat transfer coefficient.

A metal tube having fins ( i.e., metal plates, jointed to the tube, perpendicular to its length ) to transfer heat from the tube to the surrounding air. We are well-equipped with advanced facilities, which enable us to manufacture and supply top-notch quality Finned Tubes.

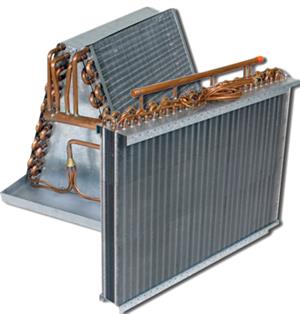

Evaporator Coils

Description / Specification of Evaporator Coils

We are involved in offering a wide range of Evaporator Coils to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Evaporator Coils. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Condensor Coils

Condenser coils usually consist of arrays of copper tubes that penetrate at right angles closely stacked aluminium plates. These plates provide a system of continous fins for enhancing air-side heat transfer.Even though air cooled condenser coils can be cooled by natural convection, they are usually installed with fans.

An evaporator is a device used to turn the liquid form of a chemical into its gaseous form. The liquid is evaporated, or vaporized, into a gas. It can also be used to remove water or other liquids from mixtures. The process of evaporation is widely used to concentrate foods and chemicals as well as salvage solvents. One of the most important applications of evaporation is in the food and beverage industry. Foods or beverages that need to last for a considerable amount of time or need to have certain consistency, like coffee, go through an evaporation step during processing

Brass Radiators

Radiators are heat exchangers used to transfer thermal energy from one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in automobiles, buildings, and electronics. The radiator is always a source of heat to its environment, although this may be for either the purpose of heating this environment, or for cooling the fluid or coolant supplied to it, as for engine cooling

Copper Radiators

Description / Specification of Copper Radiators

We are involved in offering a wide range of Copper Radiators to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Copper Radiators. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Pressure Vessels

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Pressure vessels can theoretically be almost any shape, but shapes made of sections of spheres, cylinders, and cones are usually employed. A common design is a cylinder with end caps called heads. Head shapes are frequently either hemispherical or dished. Pressure vessels are used in a variety of applications in both industry and the private sector.

Charge Air Coolers

A charge-air cooler is simply an all-encompassing term, meaning that it cools the turbo's air charge before it is routed into the engine. Usually a charge-air cooler means an air-to-air cooler where the heat is rejected using ambient air flowing through the heat exchanger, much like the engine's coolant radiator.

In general, an intercooler or aftercooler is said to be a Charge-Air Cooler.

Compressor Tank

Air Compressor Tanks offered provide for perfect support as storage tanks and can be made available in stainless steel metal construction as well as with high pressure handling capacity as per the specifications provided by the customers. These tanks are suitable for storage of air as well as providing for stable output air pressure. Some of its features include support reduction in temperature of air channel; support removal of water, dust and other impurities; quality material finish for lasting performance; blasted finish of tans both from inside and outside for best surface quality; choice of tanks in different finish dimensions

Storage Tanks

Storage tanks are containers that hold liquids, compressed gases (gas tank) or mediums used for the short- or long-term storage of heat or cold. Storage tanks are often cylindrical in shape, perpendicular to the ground with flat bottoms, and a fixed or floating roof. Storage tanks are available in many shapes: vertical and horizontal cylindrical; open top and closed top; flat bottom, cone bottom, slope bottom and dish bottom.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.